PowerPlus™ Power Supplies for Electrostatic Precipitators

NWL is the leading manufacturer of high voltage/high frequency switch mode technology power supplies for use in powering electrostatic precipitators (ESPs). PowerPlus™ units integrate the controller, the current limiting element and the T/R set functions into one compact high voltage power supply for use on the ESP.

PowerPlus™ Models

NWL offers the following PowerPlus™ models shown by kV rating:

- 70kV – used with 300mm plate spacing

- 83kV – used with 400mm plate spacing

- 100kV – used with 500mm plate spacing

PowerPlus Design Features

Carrying on the tradition of supplying the most advanced power supplies for electrostatic precipitators, NWL began design and manufacturing of the PowerPlus™ in 2000. The use of Insulated Gate Bipolar Transistors (IGBT) provides for a power supply design that operates at a much higher frequency when compared to the operating frequency of a conventional single phase unit.

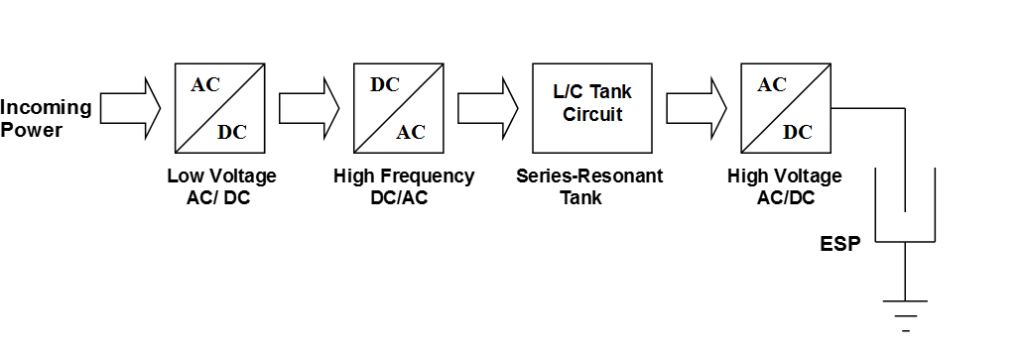

NWL’s unique integrated design, places the power supply and control system on a common assembly. The system is packaged in a NEMA 4 (IP56) rated design for outdoor installations. NWL also has a complete line of mechanical switch designs to facilitate retrofit or new installations. NWL’s PowerPlus™ is configured utilizing the following functional blocks:

PowerPlus Benefits

The NWL PowerPlus™ has been installed on precipitators in many different industries and applications throughout the world. This product has proven to provide the following benefits to its users:

- Increased collection efficiency

- Decreased kVA for the same amount of power applied to the field

- Faster spark response with less wasted spark current

- Higher Reliability

- Significantly higher power factor when compared to a conventional TR

- Lower initial installation cost

- Reduced space requirement with integrated design

- Able to facilitate buss and guard or cable for HV connection

The PowerPlus™ Design Process – Built on Proven Technologies, With Enhanced Ruggedness and Better Cooling

In 2000 when NWL entered the switch mode power supply market, there was a design decision to be made – make the smallest and lightest power supply solution or design a unit that is positioned to deal with arcing loads installed in often hot and dirty locations. NWL’s design team chose the latter and as a result came to market with a switch mode power supply (PowerPlus™) that provides:

- A series resonant topology and control mode that turns the power supply into a current source that does not rely solely on the electronics acting quickly to limit the current, but, that the circuit itself, under shorted conditions, is inherently current limiting.

- A cooling system that does not require air filters and minimizes plant maintenance. The heat sink fin spacing is such that the IGBT cooling is not degraded as dust and dirt cannot accumulate and “clog” the fins; no air enters the control box, it is completely sealed.

- A power supply that is manufactured using proven methods previously used in conventional T/R sets. The result a unit that provides the lowest total cost of ownership and integrates with existing infrastructure.

During the first several years of production, NWL put this new switch mode technology into the industries’ toughest environments. NWL then worked with users to continuously to improve the reliability of the product to obtain the high level of reliability that exists on the product being shipped today.

Today’s NWL PowerPlus™ unit has a design that more closely resembles a conventional transformer rectifier than the other switch mode units in the market. The rugged design approach detailed in the three points above has been field validated as the necessary formula for a power supply that is rugged and reliable in the environment of an ESP roof top.