PCAMS

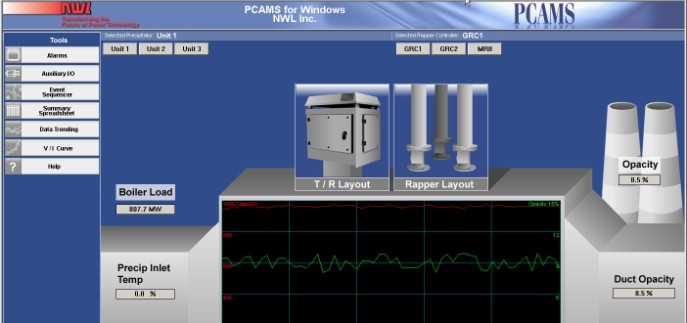

NWL’s Precipitator Control and Management System (PCAMS) changed the way industry managed its precipitator operations. Now PCAMS – designed for use with Microsoft Windows™ operating systems – offers a revolutionary new, icon-driven approach to precipitator monitoring and control. PCAMS is an NWL-developed proprietary software package that provides the ability to monitor and control NWL’s precipitator control systems from a centralized point. One PCAMS computer can control multiple precipitators.

NWL leveraged years of in-depth experience with precipitator monitoring to create a completely new and comprehensive graphic user interface. The result is PCAMS, which puts users in direct control of the following equipment:

- 8 precipitators

- 90 PowerPlus or T/R sets per precipitator

- 8 Graphic Rapper Controllers per precipitator

- 8 ash hoppers

The controller dashboard allows users to answer all important questions at a glance:

- How is the precipitator performing?

- What’s the load in kilowatt hours?

- What’s the boiler load?

- Duct opacity?

- Stack opacity?

- PowerPlus and/or Transformer/Rectifier (T/R) performance?

- Inlet and outlet gas temperatures?

All of this information, and more, is displayed right up front with time-based performance graphs, charts, or spreadsheets providing instant visual confirmation.

Industry Leading Improved Graphics

NWL has recently upgraded PCAMS’ display graphics so that equipment parameters and menu navigation is accomplished with simple mouse clicks. Click on the Photo Gallery tab to see the screen shots.

With PCAMS, maximum information is available in real time. It allows users to compare, plot, and trend T/R output, primary voltage, primary current, arc rates, conduction angle, and other critical parameters. When detailed information is required, or precipitator performance needs to be fine tuned, PCAMS’s submenus provide the widest range of control options in the industry.

Additional features include:

- Easy icon-driven approach for control of ESP voltage controllers, T/Rs and rapper controls

- Quick display of ESP performance, load kW, boiler load, duct opacity, T/R performance, etc.

- Built in trend analysis of critical parameters

- Data access from anywhere, anytime

- Cost savings via Energy Management option

- Optional OPC server for connection to plant data systems.